Metal Substitution

Plastics replace Metals

Metal Substitution

Plastics replace Metals

Plastic as a replacement for aluminium, zinc and magnesium die casting

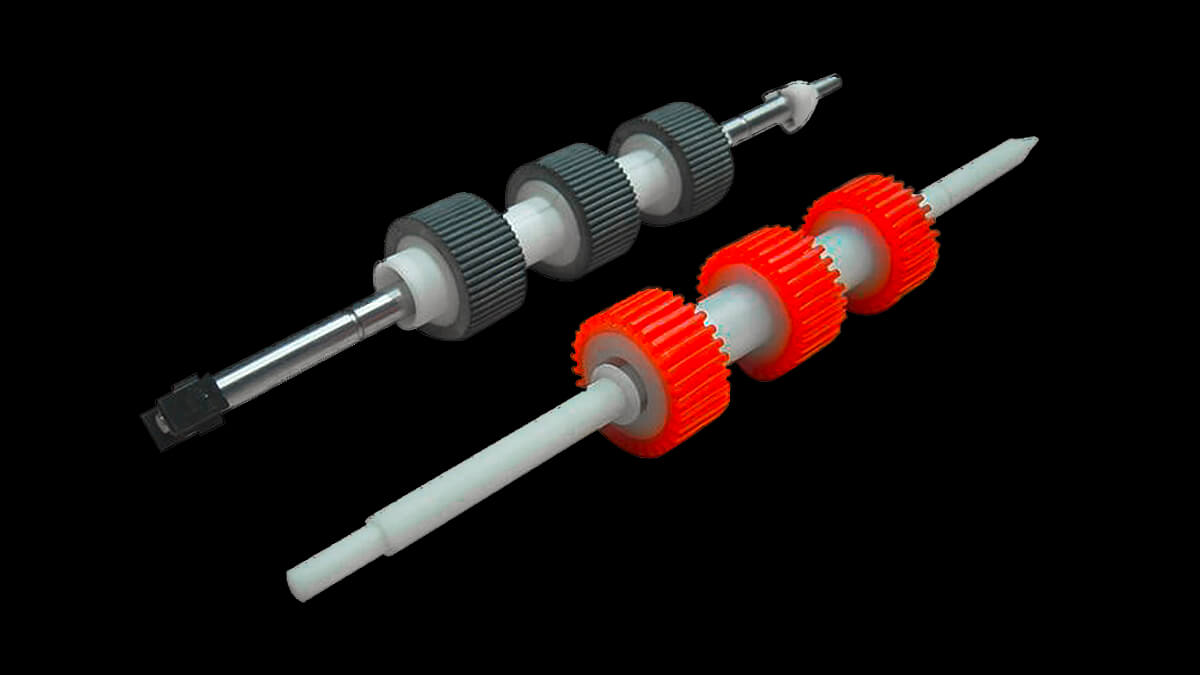

In many application cases thermoplastics are excellently suited as substitutes for metals and offer many advantages at the same time.

Thermoplastics have a low mass, better insulation and produce less noise. They offer higher functional integration, allow a better design to product differentiation and can thus usually significantly lower the costs of the whole product manufacturing process.

Special corrosion measures or later coatings can for example be dispensed with.

Advanced plastics today achieve an elasticity coefficient of almost 30,000 MPa!

Lowered system costs are one of the main reasons for substituting metal with plastic.

Advantages of metal substitution

- Integration of functions

- Lower number of parts, simplification of manufacturing, etc.

- No more expensive finishing and mounting steps such as burring, sandblasting, tempering, turning, milling, thread cutting, etc.

- Considerably higher service lives than with die casting

- (>1,000,000 shots)

- Threads can be moulded simultaneously

- Even complicated tool sliders can be used

- Weight reduction

- Noise reduction

- Recyclable (“green materials”)

- High strength and rigidity (elasticity coefficient up to almost 30,000 MPa)

- Electrically conductive materials

- Galvanisable

- Targeted improvement of product properties (e.g. impact resistance, corrosion stability)

- Narrow tolerances

- No more surface treatment necessary (coating, corrosion protection, structuring)

- Simpler handling (manufacturing, storage, transport, mounting)

- Filling studies for process optimisation possible

Successful metal substitution projects require special rules which should be observed during the product creation process.

We will gladly advise you in selecting the material and manufacturing process best suited to your product.