We make ideas plastic!

Developing ideas together

We make ideas plastic!

Developing ideas together

Developing

The optimum solution and perfect product is at the centre of our company philosophy. Our long years of experience in the development and implementation of ideas in plastic products puts us in a position to master even difficult challenges. We work out the optimum solution to problems in dialogue with our clients. Besides personal discussions, the latest means of communication provide rapid and cost-saving understanding.

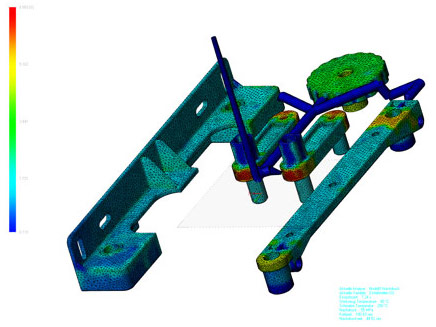

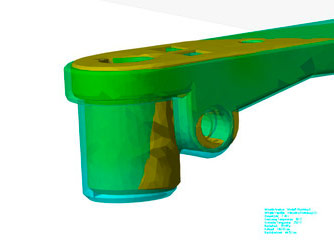

Filling studies

We rely on simulating the ideas to be implemented right from the start. Stress situations can be reconstructed using FEM calculation so as to arrive at the optimum material and geometrical configuration. Before machining of the injection moulding tool begins, filling analyses are employed to guarantee an optimum melt flow so that your product can be reliably manufactured in flawless quality.

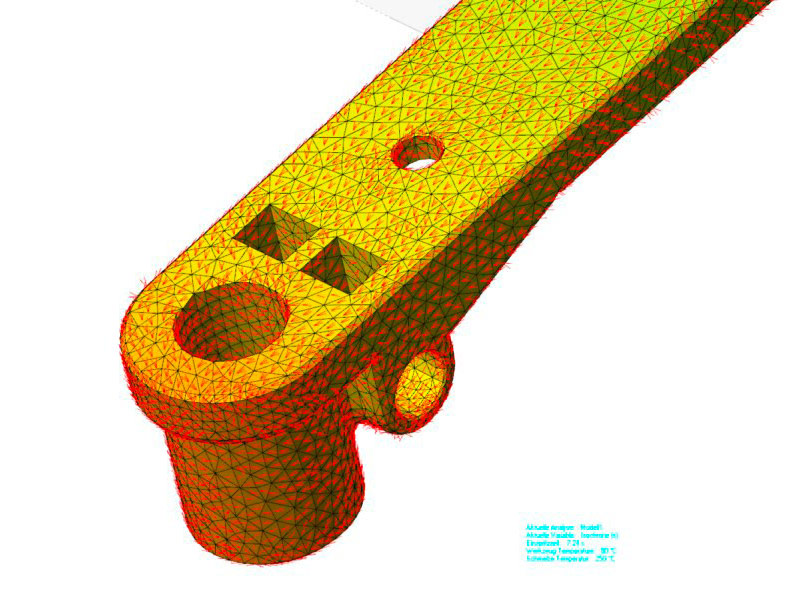

Fibre alignment

The cooling process of a plastic part involves an unavoidable distortion which is influenced by shrinkage interference (geometries, fibres, etc.).

Distortion analysis can specifically implement a defined “prestressing” in the tool, so that parts will pull themselves straight, as it were, enabling parts to be produced according to the drawing.

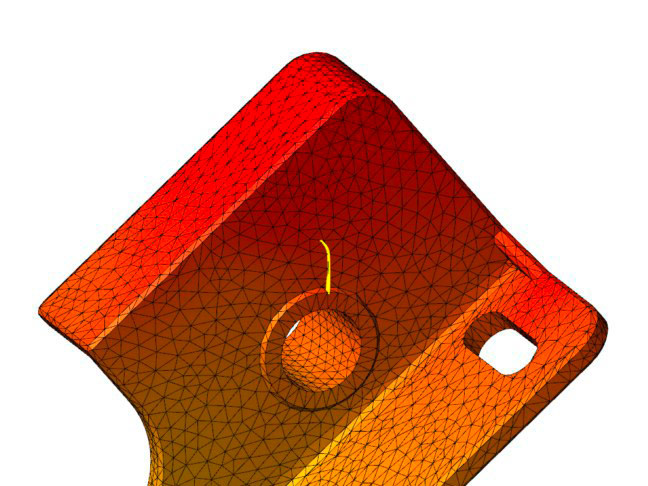

Joint lines and air pockets

Injection moulding can lead to joint lines and air pockets during mould filling when flow fronts meet each other. These places can form weak points in the article. To obviate this, preliminary simulation is employed to anticipate these positions and introduce specific structural changes to the tool.

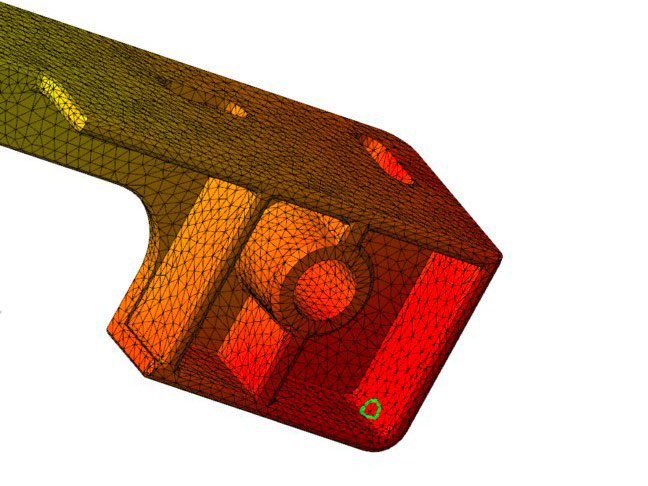

Distortion

The cooling process of a plastic part involves an unavoidable distortion which is influenced by shrinkage interference (geometries, fibres, etc.).

Distortion analysis can specifically implement a defined “prestressing” in the tool, so that parts will pull themselves straight, as it were, enabling parts to be produced according to the drawing.

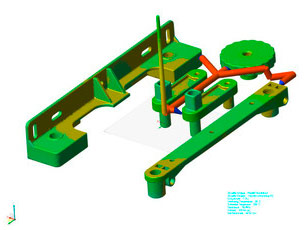

Construction – Turning ideas into forms

Close collaboration with our clients produces optimally designed geometries that guarantee relia-ble manufacturing of an article. Your ideas are translated into structures with the latest CAD systems. The process relies on the long-standing experience of our competent team of developers and design engineers and the con-tinuous qualification of our up-and-coming young designers.

Our systems are equipped with all the usual interfaces, so that delays and losses in data exchange are not an issue.

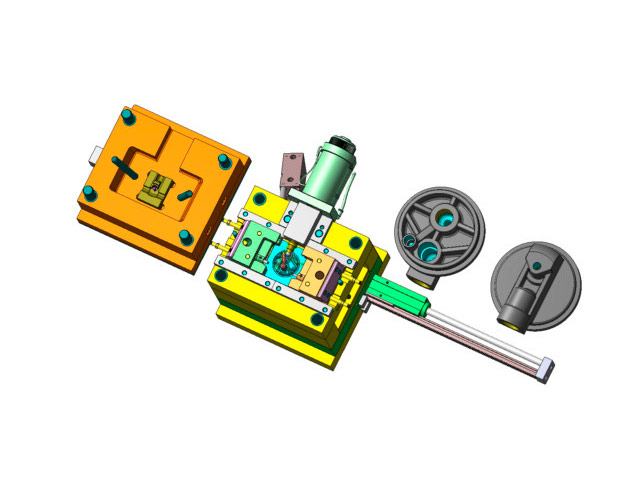

Tool & mould making – realising special forms

Design engineering moves seamlessly on to our in-house toolmaking process. Computer controlled machine tools are supplied online via 3D-CAM with the data created in the design engineering process, so as to convert them into the necessary injection moulding forms. The latest CNC technology guarantees the required precision.

Rapid prototyping allows economic production of prototypes with a high standard of quality for short-term projects. The tools are maintained and stored by us with the same care with which we build them. We can thus give you the assurance that repeat orders can be processed promptly and in the accustomed high quality.

The high degree of perfection in this department is a result of the know-how of our long-term, optimally trained employees. To build on a base of qualified personnel in the future as well, these are thoroughly trained within the organization. This ultimately also leads to a very efficient work-ing practice which benefits our clients to the fullest extent in the form of economic prices.

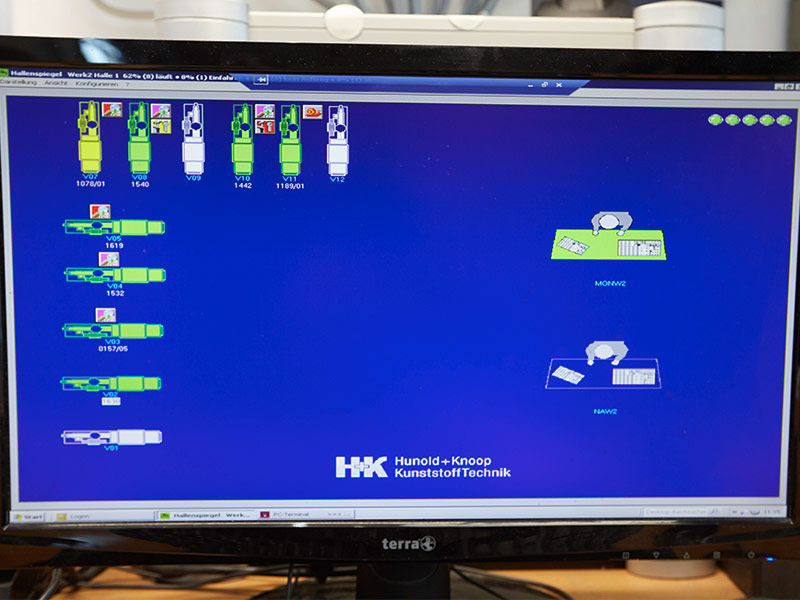

Injection moulding – Finished form production

We manufacture your products on a total of 57 injection moulding machines with locking pressures of up to 500 tonnes and part weights of up to 2,000 grammes. Targeted investment in keeping our modern machine park up to date means we can sustainably offer maximum performance.

With a state-of-the-art MES system (PDE/CAQ) all machines are interconnected and, visualized via control station technology, can be viewed and monitored at any PC workstation.

A wide range of inserts, especially in metal, for various automobile suppliers and for machine construction, are extrusion-coated with high-technology special polymers or other materials. This area also includes the manufacture of extrusion-coated spindles, rollers and cylinders with sub-sequent grinding.

Recycling – Recondition old components

It is not only the design and manufacture of new products that are part of our range of services – environmental protection is also important to us. That is why we also offer our services in the field of recycling of overmoulded shafts.

A service representative – or yourself – removes the old, worn-out part and send it to us. We renew your used steel shaft by removing the plastic residues and coating the shaft with new material in compliance with all quality requirements – and you can continue to use your steel shaft!

Recycling wastes fewer raw materials, which reduces the impact on the environment. In addition, you have the advantage that by reusing your core material, you save costs and the purchase of a completely new overmoulded shaft is not necessary for the time being.