Spindles, Rollers and Cylinders

For printers, copiers and ATMs

Spindles, Rollers and Cylinders

For printers, copiers and ATMs

A speciality of Hunold + Knoop is the overmoulding of shafts, rolls and rollers with “soft” and “hard” thermoplastic materials. We are the world market leader in this area.

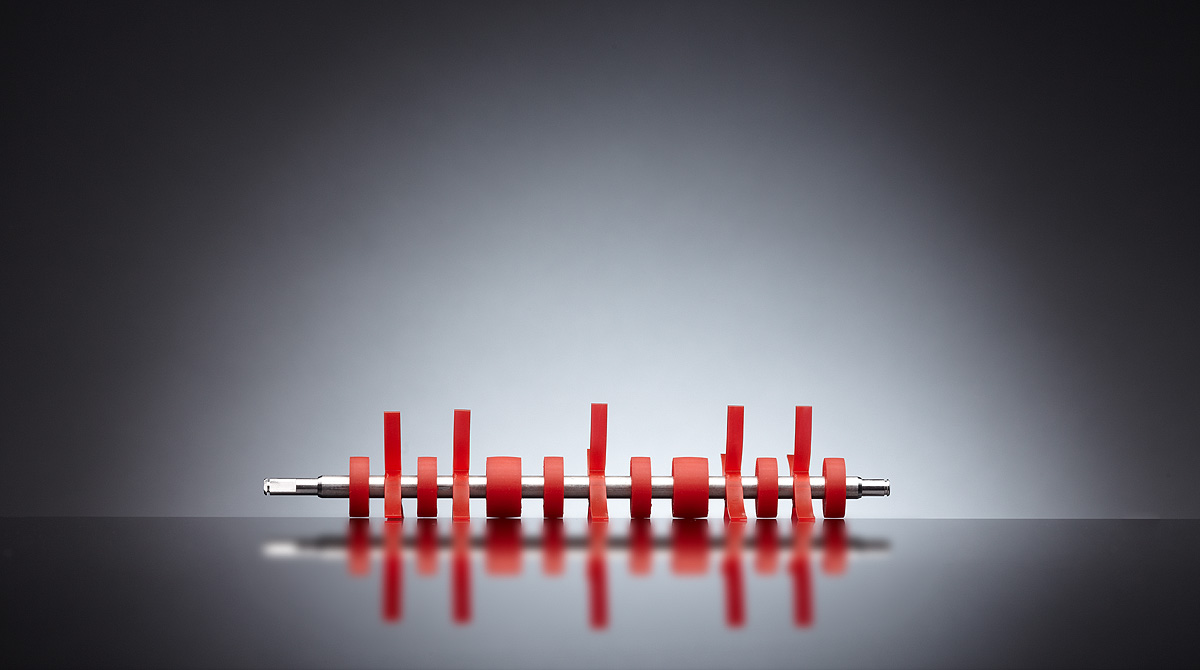

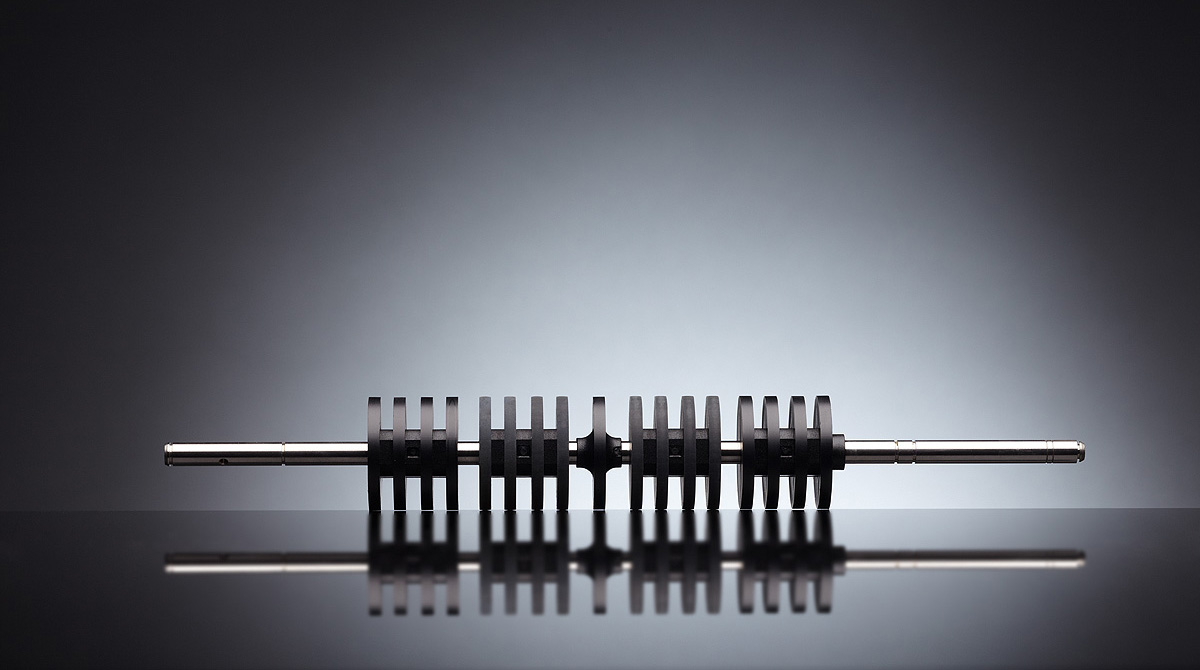

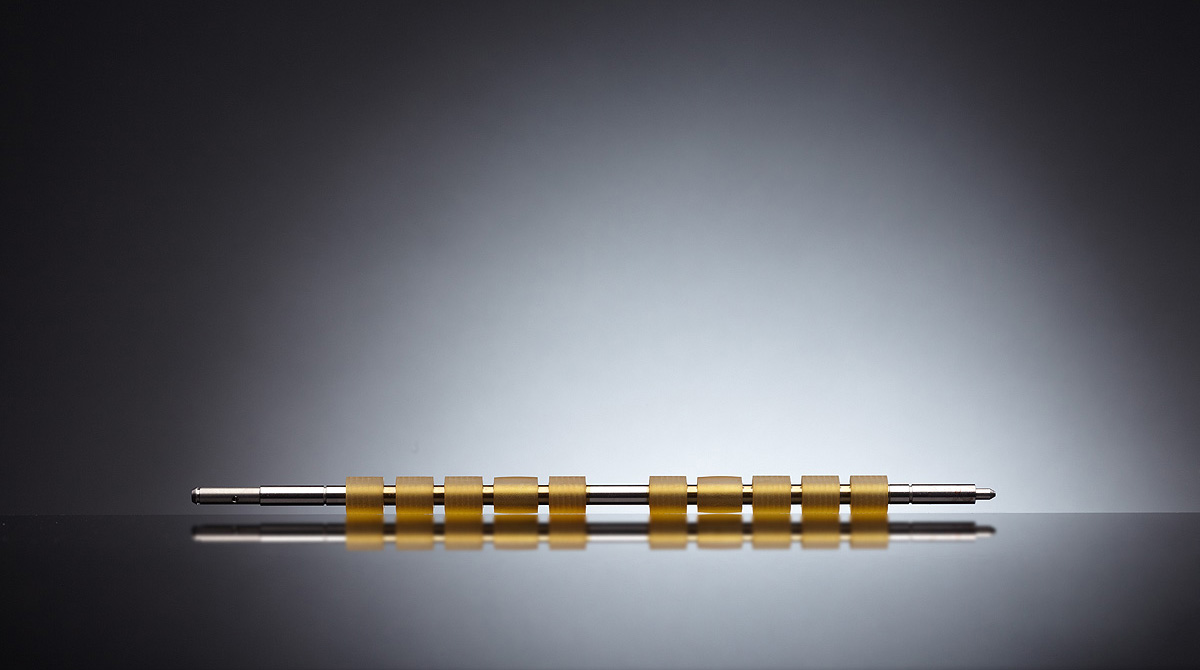

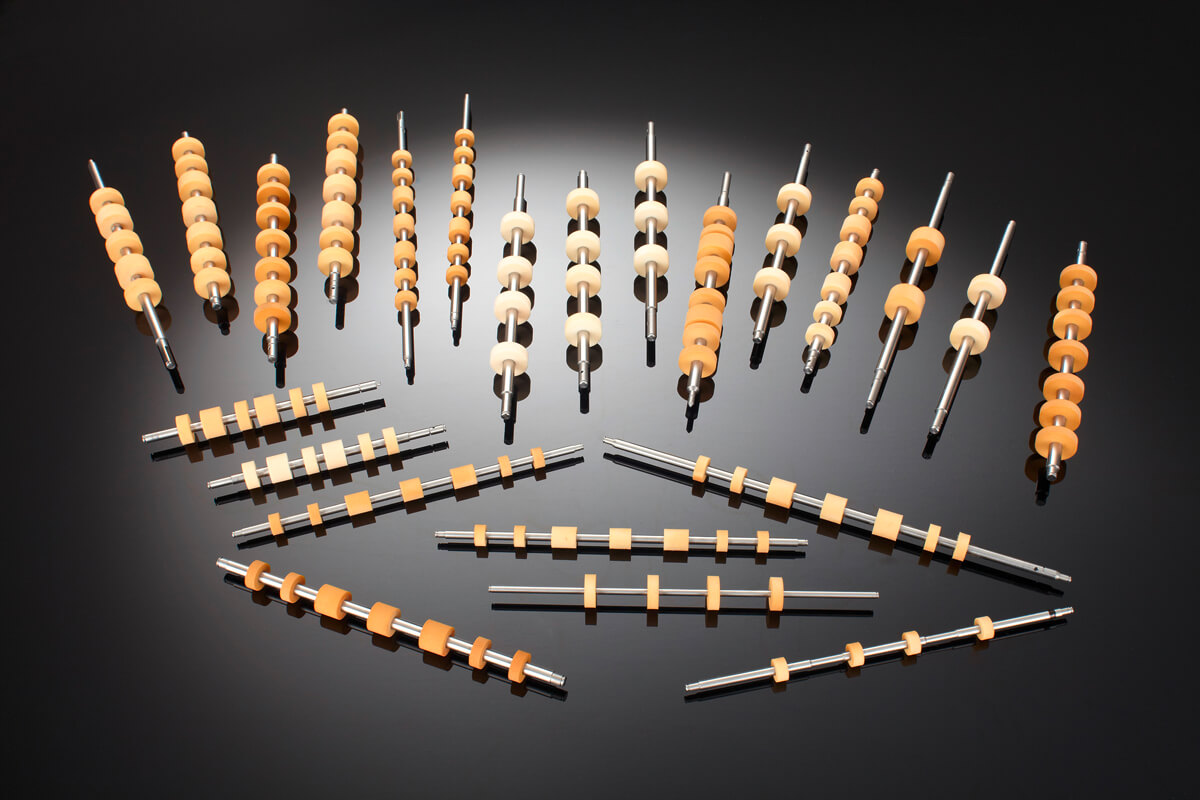

Paper transport in digital printing systems is a particularly sensitive area. We rationally and reliably produce the most varied axes for the transport units. Our CNC-controlled long automatic lathes, which are deployed along with CNC-controlled lathes, produce spindles, axes and other designed components with the greatest precision.

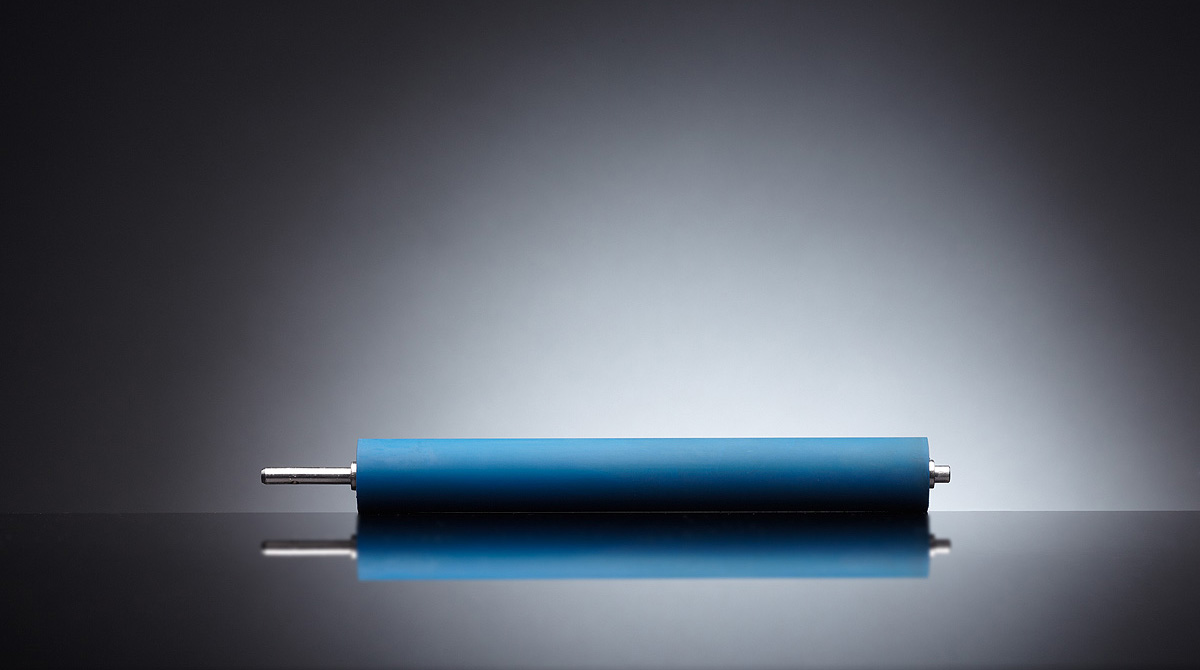

A speciality at Hunold + Knoop is the extrusion coating of spindles, rollers and cylinders with “soft” and “hard” thermoplastics.

The high-precision components are CNC-ground and the quality is guaranteed by means of the latest laser measuring technology.

Numerous applications in the areas of the office (printers and copiers etc.) and cash machine in-dustries have been realised in the past few years.

- Special cylinders

- Rollers and spindles

- From drawings or samples

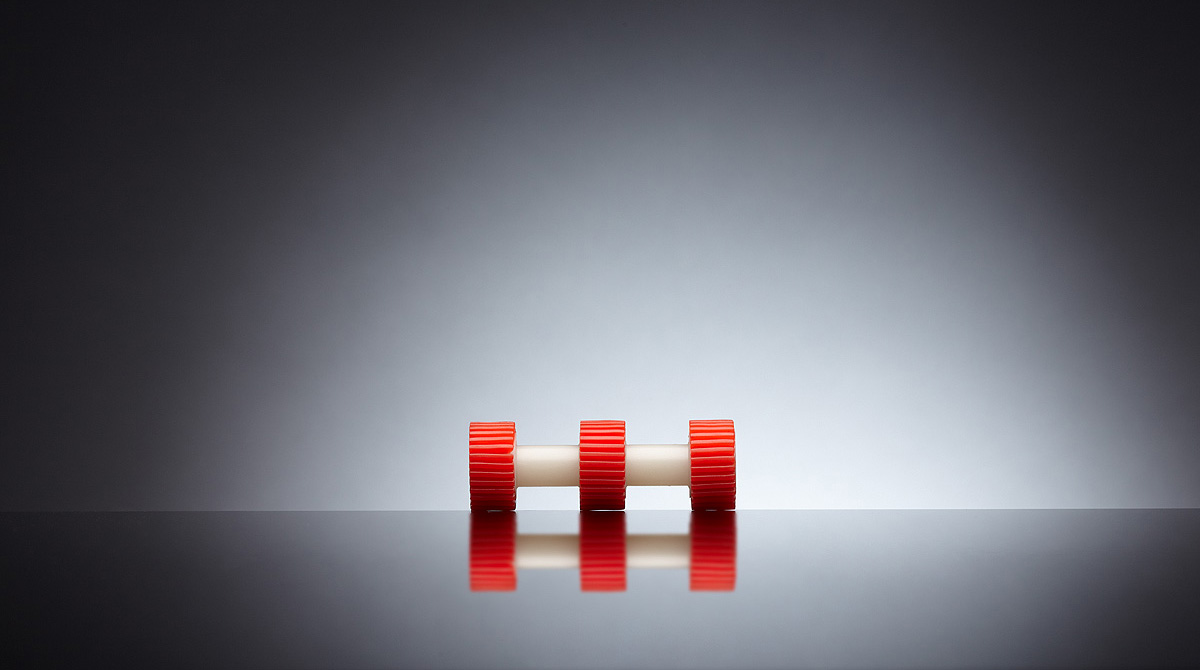

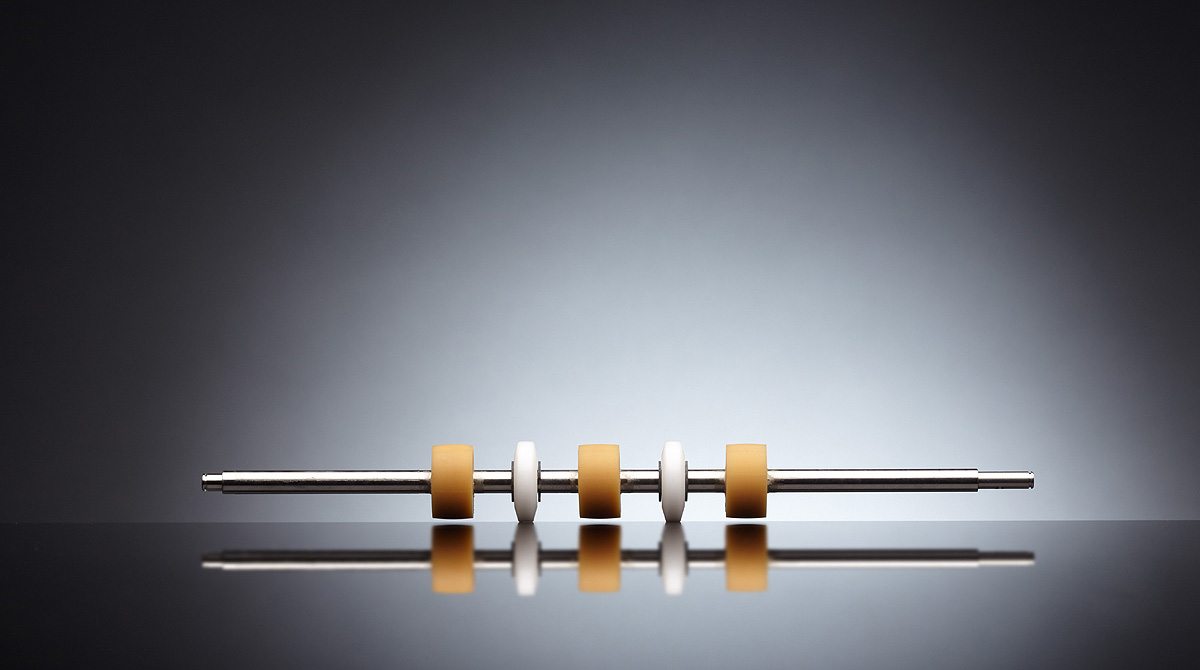

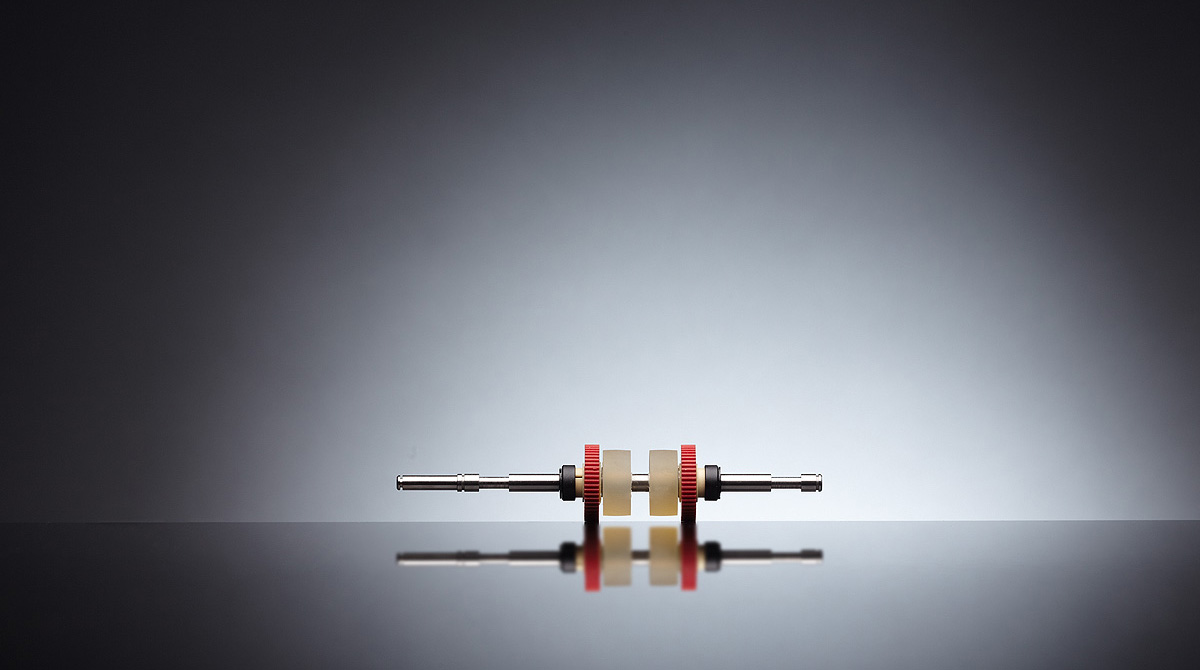

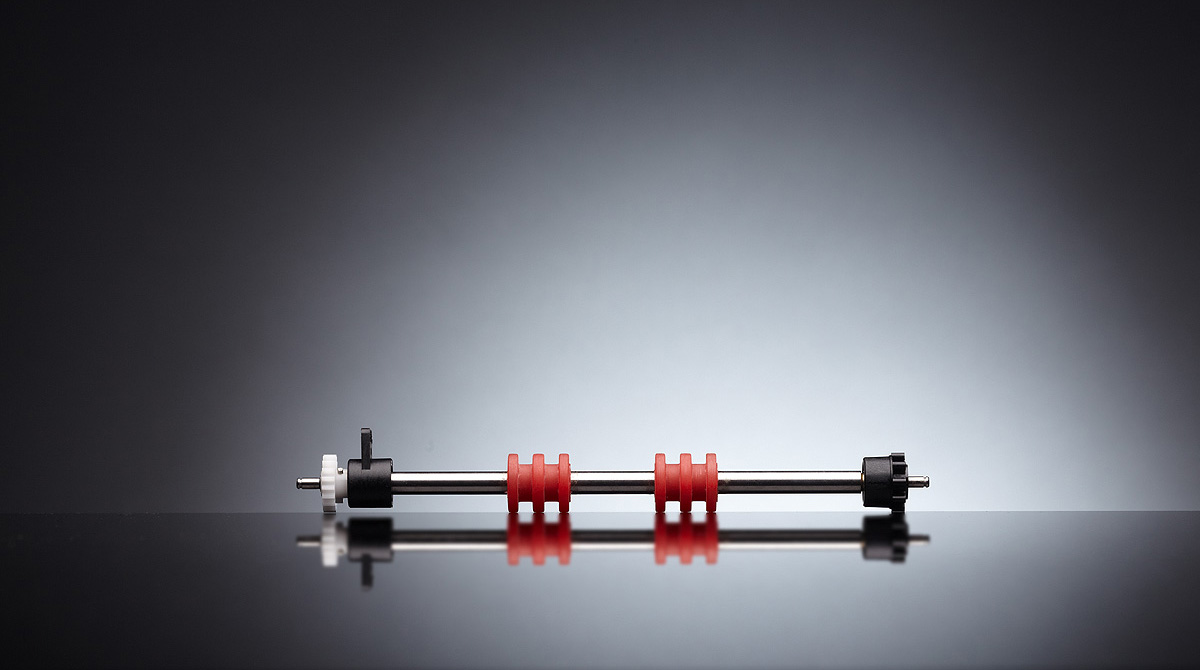

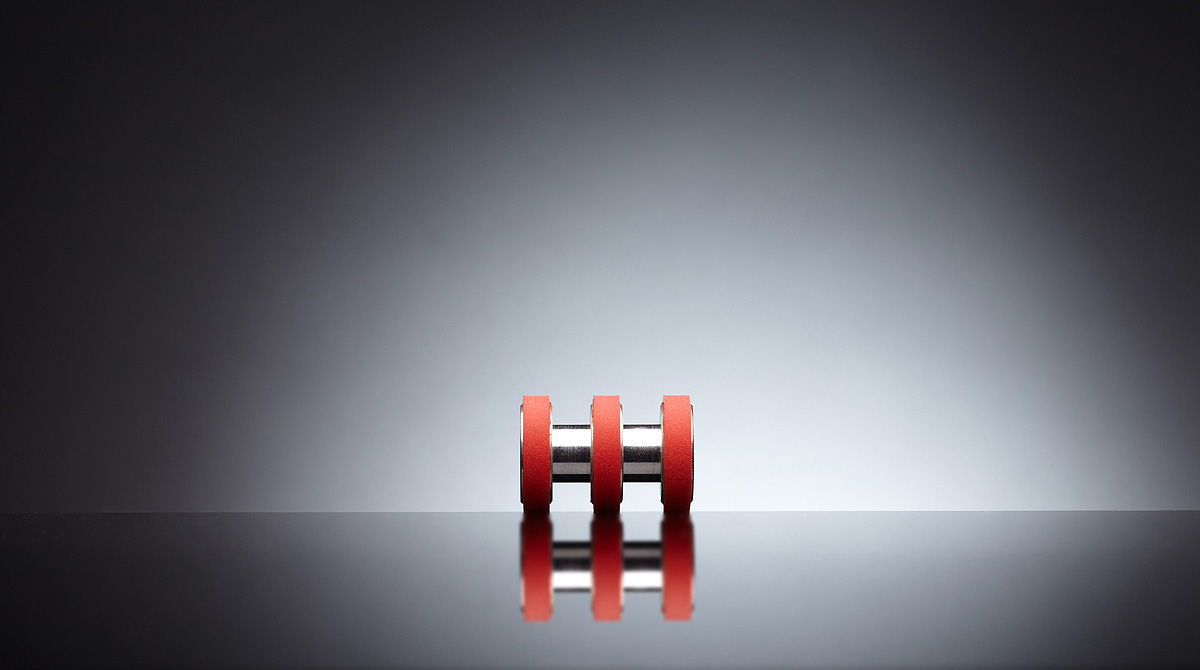

Extrusion-coated and ground to a hundredth of a millimetre 2-component pinch rolls assembled as one complete component.

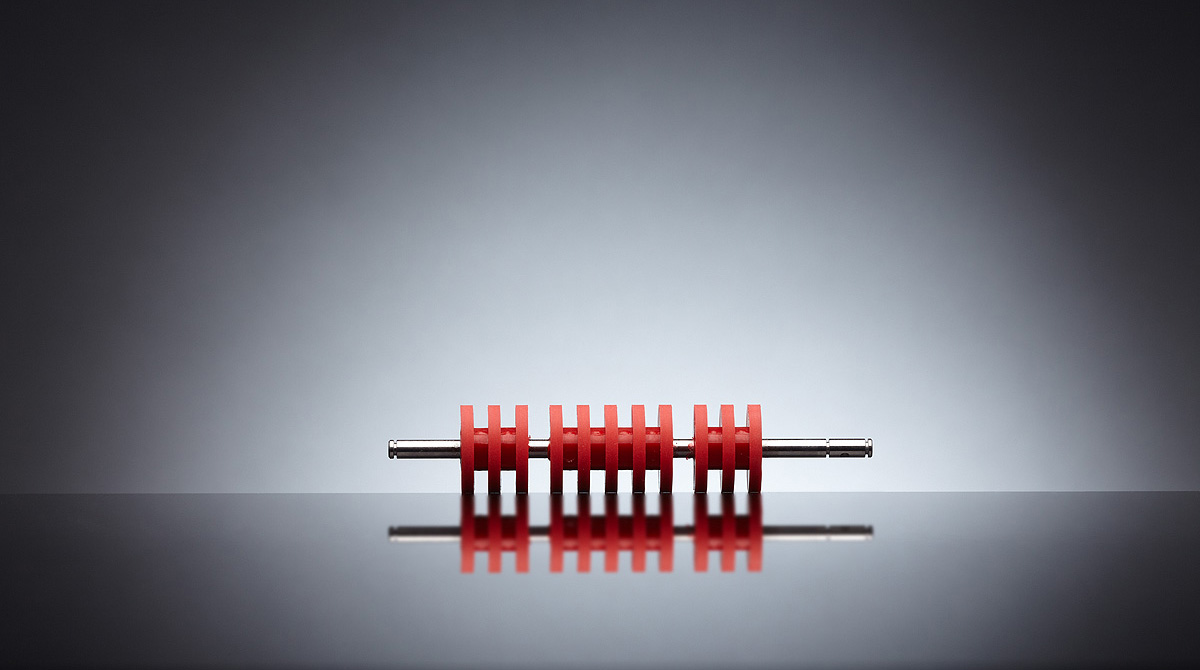

Extrusion-coating with “soft”, rubber like plastics, e.g. TPU (polyurethane) or TPE (thermoplastic elastomers) and subsequent precision grinding of components.

Extrusion-coating with “hard” plastics and subsequent contour grinding on CNC machines.

Product range

- 2-component rollers

- Pressure rollers

- Drive rollers

- Printing rolls

- Feed rollers

- Conveyor shafts

- Foamed rollers

- Rubberized shafts

- Plastic PU rollers

- Paper feed rollers

- Transport rollers

- Pinch rolls

- Deflection shafts

- Feed rollers

- Rubber rollers

RECYCLING OF OVERMOULDED SHAFTS

Through daily use, the shafts wear out over time due to friction and need to be replaced sooner or later. However, a new component is not absolutely necessary – we will take back your old part and renew it for you! We remove the plastic rollers/residues from the steel shaft and coat them again with new material – of course in compliance with all quality requirements.

So do not dispose of your used or damaged steel shaft immediately, but simply use it again – recycling saves raw materials, money and the environment!