TPU-X®

Competition for Rubber Elastomers

TPU-X®

Competition for Rubber Elastomers

„Wherever technological life gets tough is where our TPU-X® feels at home.“

M. Hunold

The premium material TPU-X® is deployed anywhere where the highest performance is required. The revolutionary material properties of cross-linked polyurethane (TPU-X®) are what make this new material so unique. High stresses in machine and plant construction become manageable with TPU-X®.

A moulding process patented by Hunold + Knoop has made it possible to considerably simplify and speed up the cross-linking process.

High stresses in machine and plant construction become manageable with TPU-X®.

The advantages of TPU-X®

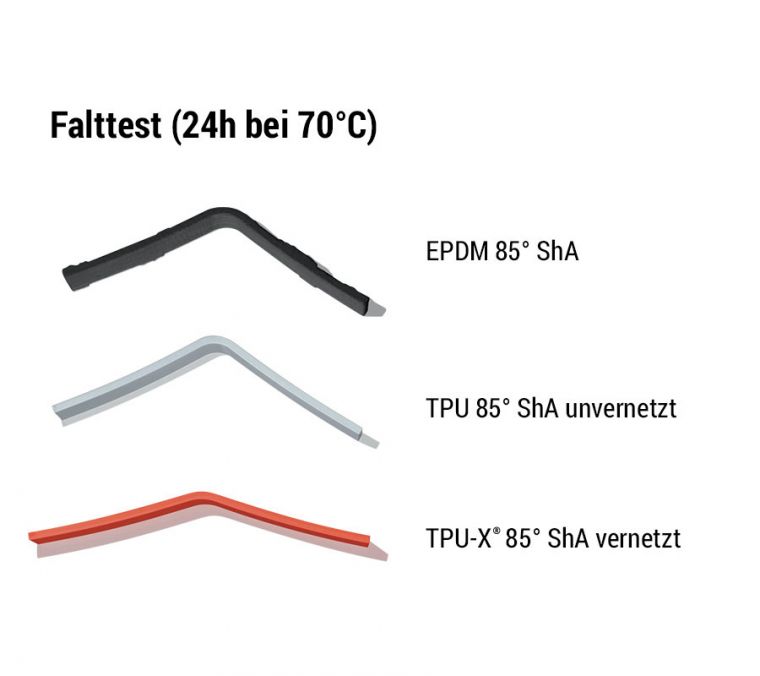

- Rubber-elastic properties

- Enormous dynamic properties

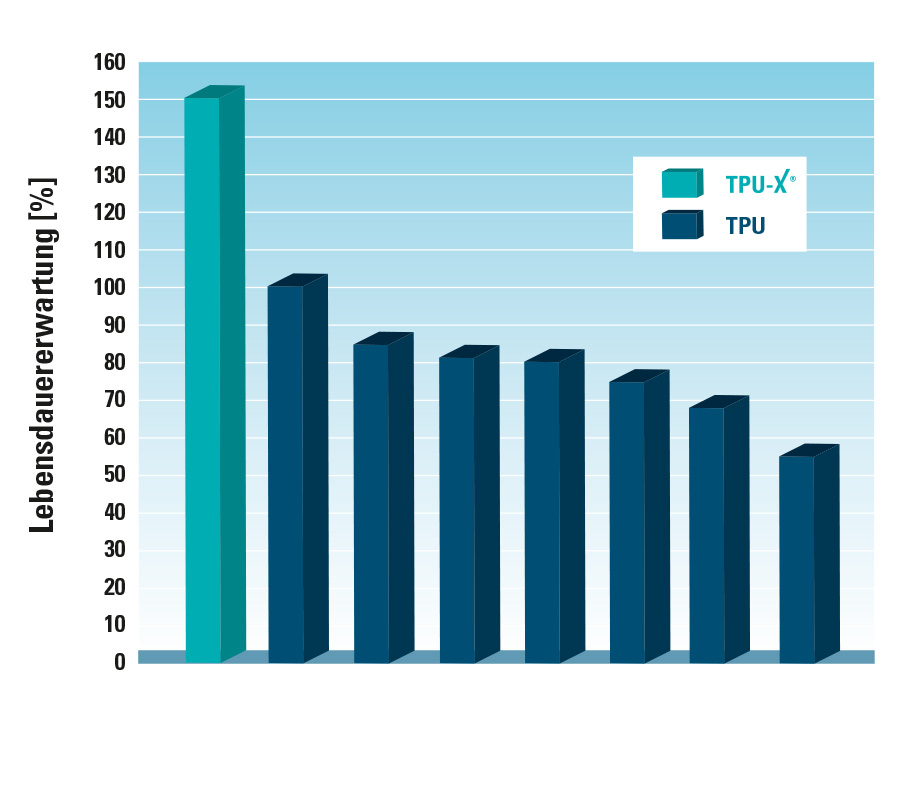

- Considerably increased life expectancy under extreme conditions

- Extremely high resilience

- Very high level of “snappiness”

- Lower abrasion

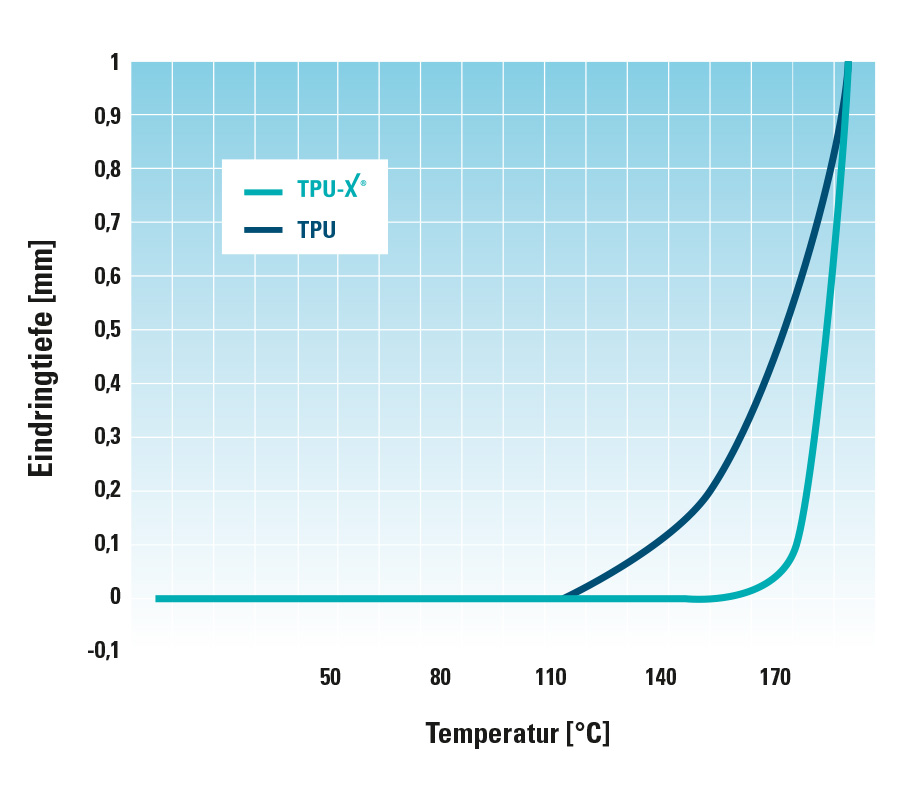

- Continuous working temperature up to +120°C

- Short-term max. temperature up to +150°C

- Excellent oscillation and vibration dampening (NVH)

- Drastically shortened process chain compared to expensive vulcanisation

- Short cycle times

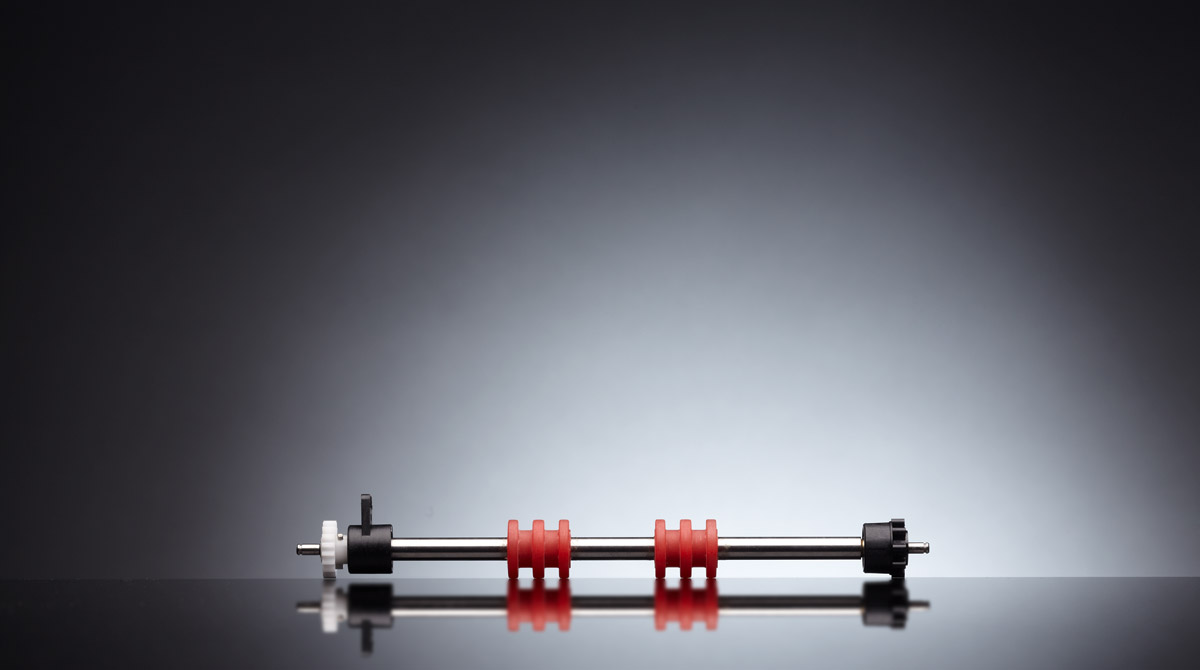

- 2K material combinations with other technical plastics and metals

- Settings from approx. 45°ShA to 74°ShD

- Oil and grease-resistant

- Ozone-resistant

- Odourless

- Storage stable in contrast to rubber

Areas of application include:

- Sealing technology

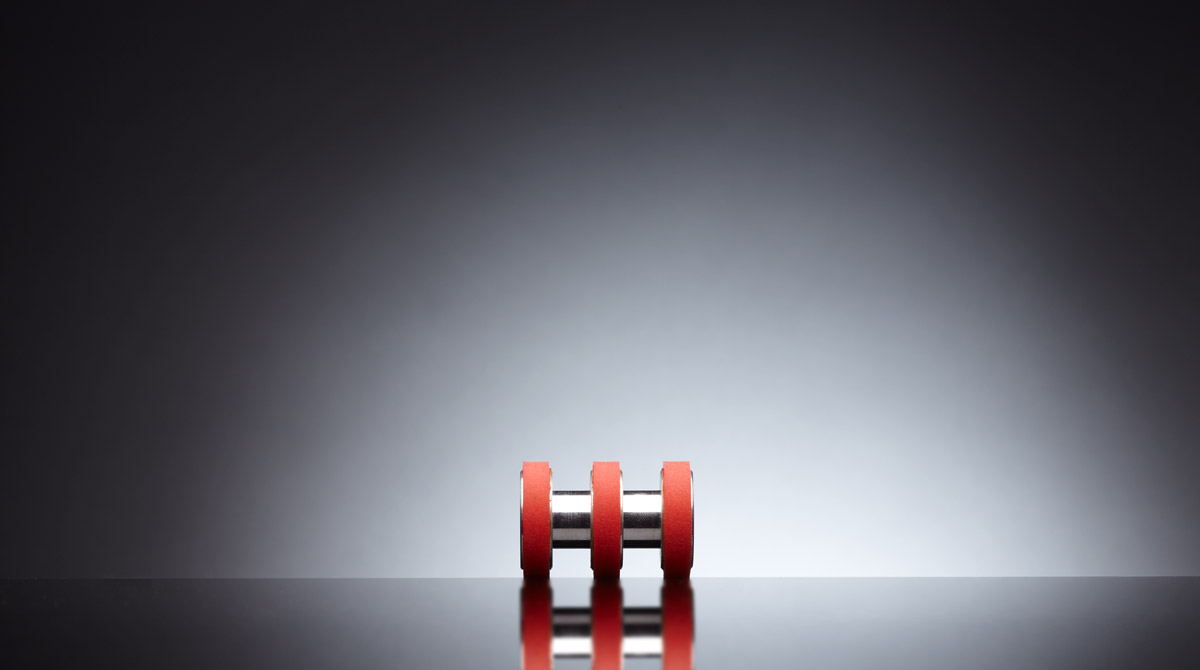

- Gear wheels (substitution of POM, PA, since more flexible)

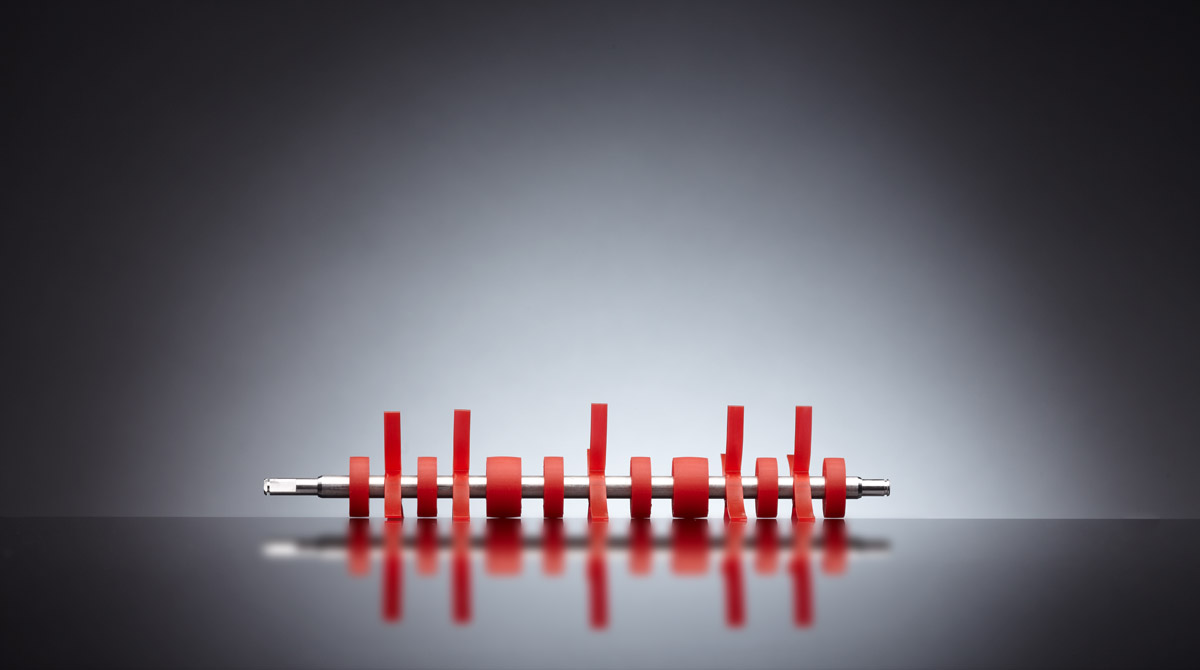

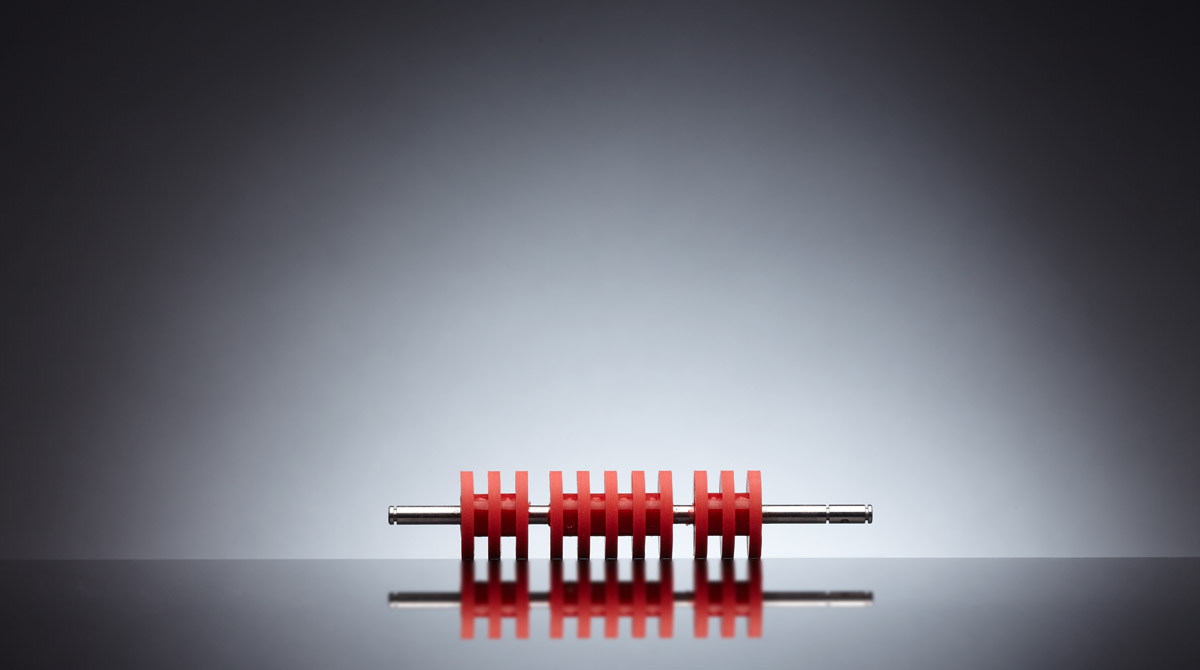

- Rollers, cylinders and spindles for paper transport

Examples of products

References

“The output in our sieving plants has increased by 10-12% with the new TPU-X® sifter balls. The operating time of the balls even increased 3-4 fold.”

“TPU-X® offers unbeatable benefits for many applications. Costs are reduced – and higher quality, more resilient parts are produced. Valuable pioneering work is being performed here by Hunold + Knoop.”